Day 3 :

Keynote Forum

Seema Singh

Joint Bioenergy Institute, USA

Keynote: Enabling bioeconomy and sustainability: technologies for fuels and chemical production from lignocellulose

Time : 09:00 - 09:30

Biography:

Seema Singh is a biophysicist and a guest senior scientist with the JBEI Deconstruction Research Division & a director of Biomass Pretreatment. She is a distinguished member of the technical staff in Biomass Science and Conversion Technologies Department at Sandia National laboratories, CA.

Abstract:

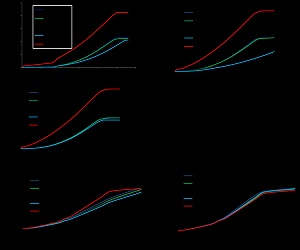

Today, carbon-rich fossil fuels, primarily oil, coal and natural gas, provide 85 percent of the energy consumed in the United States. Fossil fuel use increases CO2 emissions, increasing the concentration of greenhouse gases and raising the risk of global warming. The high energy content of liquid hydrocarbon fuels makes them the preferred energy source for all modes of transportation. In the US alone, transportation consumes around 13.8 million barrels of oil per day and generates over 0.5 gigatons of carbon per year. This has spurred research into alternative, non-fossil energy sources. Among the options (nuclear, concentrated solar thermal, geothermal, hydroelectric, wind, solar and biomass), only biomass has the potential to provide a high-energy-content transportation fuel. Biomass is renewable resource that is carbon-neutral.Currently, biofuels such as ethanol are produced largely from grains, but there is a large, untapped resource (estimated at more than a billion tons per year) of plant biomass that could be utilized as a renewable, domestic source of liquid fuels. Well-established processes convert the starch content of the grain into sugars that can be fermented to ethanol. Plant-derived biomass contains cellulose, which is more difficult to convert to sugars. The development of cost-effective and energy-efficient processes to transform cellulose and lignin in biomass into fuels and chemicals is hampered by significant roadblocks, including the lack of specifically developed energy crops, the difficulty in separating biomass components, low activity of enzymes used to deconstruct biomass, and the inhibitory effect of fuels and processing byproducts on organisms responsible for producing fuels from biomass monomers.

The Joint BioEnergy Institute (JBEI) is one of three US Department of Energy Bioenergy Research Centers that is addressing these roadblocks in biofuels production by developing the scientific and technological base needed to convert the energy stored in cellulose into transportation fuels and commodity chemicals. This talk will present a summary of the efforts at JBEI and highlight the efforts on the discovery and development of novel biomass pretreatment methods that enable the efficient conversion of biomass into next-generation biofuels. I will also discuss, examples of lignin conversion technologies being developed by my team at Sandia National Laboratories via hybrid approaches and synthetic biology.

Keynote Forum

Francisco GarcÃa Labiano

ICB-CSIC, Spain

Keynote: Bioenergy production through chemical looping processes

Time : 09:30 - 10:00

Biography:

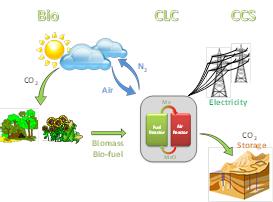

Francisco García-Labiano is currently a Scientific Researcher at the Instituto de Carboquímica in Zaragoza, belonging to the Spanish National Research Council(CSIC). His research has been always close linked to environmental challenges in energy production processes. Since 2000, he has been involved in the development of the Chemical Looping Combustion (CLC), one of the most promising technologies within the area of CO2 Capture and Storage (CCS) aiming to reduce global warming. More recently he has been actively engaged in the use of renewable fuels, such as biomass, bioethanol, etc. in Chemical Looping processes (bio-CLC) with the main objective to reach negative CO2 emissions in energy processes. He is the author of more than 150 publications in international peer reviewed journals, 3 patents, etc. He has been recognized as Highly Cited Researcher by Thomson Reuters within engineering area in years 2015 and 2016.

Abstract:

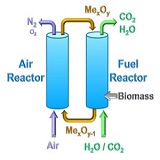

This work presents an overview of the recent advances in bio-CLC technology within the key strategies arising nowadays to mitigate climate change. The Paris Agreement, the new treaty of the United Nations Framework Convention on Climate Change (UNFCCC), urges to decarbonize the world energy systems in the near future in order to limit the increase in the average world temperature to 2ºC above pre-industrial levels. To reach this goal, CO2 emissions should start to decrease by 2020 and become negative by the end of the century. Among the different options, most of the low-carbon scenarios rely on the use of BECCS (Bioenergy and Carbon Capture and Storage) as mandatory technologies to reach negative emissions. In this sense, Chemical Looping Combustion (CLC) is considered one of the most promising CCS technologies for power plants and industries because its inherent CO2 capture avoids the energetic penalty present in other competing technologies. CLC process is based on the use of a solid oxygen carrier to transfer the oxygen from air to the fuel avoiding direct contact between them. The technology has undergone a great development during last 15 years including operational experience in continuous units and oxygen carrier’s manufacture. In addition, the new Chemical Looping with Oxygen Uncoupling (CLOU) process represents a qualitative step forward in solid fuel combustion due to the use of materials with capability to release oxygen. There are several renewable energy sources that can be used in chemical looping processes, including both solid and liquid fuels. The use of biomass in CLC represents important advantages compared to conventional biomass combustion. Besides CO2 negative balance, higher thermal efficiency, NOx formation reduction and lower corrosion in heat exchangers have been reported. In addition, several renewable liquid fuels, such as bioethanol can be also used both in combustion (CLC) and reforming (CLR) processes for heat/electricity and syngas/H2 production, respectively. In summary, the use of renewable fuels in chemical looping processes represents at this moment a very promising opportunity for future green energy development.

Keynote Forum

Animesh Dutta

University of Guelph, Canada

Keynote: Renewable fuels and products from biomass: A hybrid thermochemical and biochemical conversion process

Time : 10:00-10:30

Biography:

Animesh Dutta is an Associate Professor and Director of Bio-renewable Innovation Lab and Associate Director of graduate studies with the School of Engineering at the University of Guelph, Canada. He is specialized in advanced energy systems and thermo-fluid science with hands-on experience in reactor design and pilot plant operation, design and performance of various tests in laboratory scale and pilot scale units, thermal design and process development. His current research is focused on thermochemical conversion (gasification, combustion, torrefaction, hydrothermal carbonization and liquefaction) and characterization of agri-residue, biomass and waste (MSW, Bio-solids) for fuel and energy and design and optimization of advanced energy systems. He is committed to developing an innovative research program on energy and other value-added products from biomass and waste materials. In his career, he has published over 75 peer-reviewed journal papers, 3 book chapters and has roughly 85 conference publications and reports.

Abstract:

Food security, climate change and energy sustainability are three major challenges in the 21st century. Among different renewable energy sources, bioenergy is a renewable primary energy source that touches all three major issues due to its competition with food on land use, low net CO2 emissions and potentially sustainable if the economic, environmental and societal impacts are properly managed. The research at Bio-renewable Innovation Lab (BRIL) at Guelph focuses on research and development of a novel approach for the production of an array of renewable products such as energy, fuels and products from Canada’s particular range of low grade biomass sources. These sources range from woody biomass to agricultural wastes, municipal green bin collections and animal manures. This novel approach integrates thermochemical and biochemical conversion processes through a series of innovative technologies (i.e., hydrothermal pretreatment, supercritical gasification or anaerobic digestion with dry reforming, gas-to-liquid fuel through fermentation). The innovative and synergistic integration of design with processing through the above projects are expected to result in renewable fuels and value-added products. The resulting biocarbon can substitute fossil resources on a cost-performance basis with the added benefit of eco-friendliness. This could mean a tremendous reduction in greenhouse gas emission through the use of bioproduct, reducing our dependency on petroleum. The use of hydrothermal, chemical looping and supercritical gasification, anaerobic digestion, dry reforming of biogas to produce syngas and syngas fermentation techniques in the development and application of biofuels and products would lead to reduced dependency on petroleum and a sustainable economy.

Keynote Forum

Weilan shao

Jiangsu University, China

Keynote: Why is the thermophilic ethanol fermentation limited to low ethanol titers?

Time : 10:40 - 11:10

Biography:

Dr. Weilan Shao holds a Master degree in Plant Disease and a Ph.D. degree in Microbiology. She participated in the field of the thermophilic degradation and fermentation of lignocellulosic biomass for her PhD study (1990-1993) in the University of Georgia, USA. Dr. Shao has worked as a distinguished professor in Jiangnan University, Nanjing normal University and Jiangsu University in China. Her research mission is to develop feasible and economic effective approaches for enzyme production and renewable bioenergy processing by using molecular biotechnology. Dr. Shao and her group have discovered a series of novel lignocellulases, the key aldehyde dehydrogenase for ethanol formation, the repressor/operator system coupling glycolysis and fermentation pathways, and the regulation mechanism of thermophilic ethanol fermentation. Dr Shao also invents new techniques of gene expression system (US patent), in situ gene random mutagenesis (CN patent; US patent), novel selection marker and so on.

Abstract:

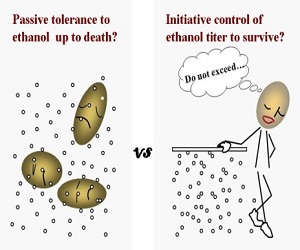

Ethanogenic thermophiles can conduct consolidate fermentation of cellulosic ethanol; however, their practical application has been hindered by the fact that the fermentation results in relatively low final ethanol titers. Metabolic engineering has emerged as a powerful tool for improving ethanol production, but it is very fundamental to understand why thermophilic ethanol fermentation is ended, and how ethanol productivity can be elevated via metabolic engineering. Thermoanaerobacter ethanolicus strains are able to grow at temperatures above 70oC, use xylose efficiently, and produce ethanol as main fermentation product. Therefore T. ethanolicus JW200 is taken as a model strain of thermophilic ethanogens to study ethanol fermentation pathway and its regulation mechanisms. After AdhE was identified as the main aldehyde dehydrogenase (Aldh) ,physiological roles of the key enzymes AdhA, AdhB and AdhE have been determined in T. ethanolicus. All the seenzymes are able to catalyze reversible reactions forethanol formation and consumption based on substrate concentrations. AdhB gene is transcribed at beginning of cell growth in the absence of ethanol; AdhB has weak but both Aldh and Adh activities which initiate ethanol formation. The trace ethanol produced by AdhB induces gene transcription to produce AdhA and AdhE which conduct active

formation of ethanol. Further accumulated ethanol will increase the reverse reactions for ethanol consumption and inhibit the transcription of all Aldh and Adh genes. The transcription of dehydrogenase genes is regulated by redox-sensing-protein, which binds to oprators of different affinities so that adhA, adhB and adhE are expressed at directed time. Traditionally, it is believed that low ethanol titer is resulted from lacking high ethanol tolerance in thermophilic ethanogens (>4%). However, presented results support a regulation theory: The limitation of final ethanol titer is achieved in thermophilic ethanogens by a systematic regulation through transcriptions and reversible activities of the key enzymes involved in the ethanol fermentation pathway.

- Special session

Location: Dorothy

Chair

Donald L Rockwood

University of Florida, USA

Session Introduction

Donald L Rockwood

University of Florida, USA

Title: Eucalyptus trees for bioenergy

Time : 11:45-12:05

Biography:

Abstract:

Ronald S Zalesny Jr

United States Department of Forest Service, USA

Title: Fast growing poplars for bioenergy

Time : 12:05:12:25

Biography:

Abstract:

Timothy A Volk

State University of New York College of Environmental Science and Forestry, USA

Title: Shrub willow for bioenergy and ecosystem services

Time : 12:25-12:45

Biography:

Abstract:

Lunch Break 12:45-13:30 @ Foyer A

- Biomass | Bioenergy

Location: Dorothy

Chair

Prabir Basu

Dalhousie University, Canada

Co-Chair

Charles M. Cai

Universitty of California Riverside, USA

Session Introduction

Prabir Basu

Dalhousie University, Canada

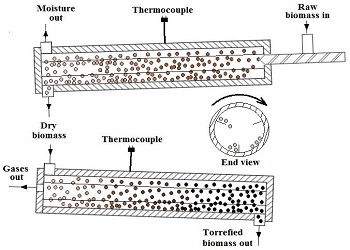

Title: A comprehensive study on production of torrefied biofuel using inclined rotary reactor

Time : 13:30-13:50

Biography:

Abstract:

Charles M. Cai

University of California Riverside, USA

Title: Biomass deconstruction towards total carbon utilization for future biorefineries

Time : 13:50-14:10

Biography:

Abstract:

Alberto Abad

ICB-CSIC, Spain

Title: Biomass combustion with CO2 capture by chemical looping

Time : 14:10-14:30

Biography:

Abstract:

Niclas Scott Bentsen

University of Copenhagen, Denmark

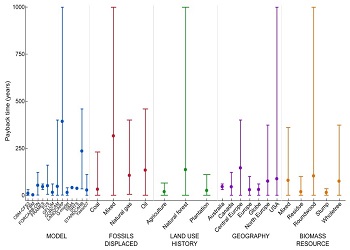

Title: Carbon debt of forest bioenergy - Fact or fantasy?

Time : 14:30-14:50

Biography:

Abstract:

Scott Sattler

USDA-ARS, USA

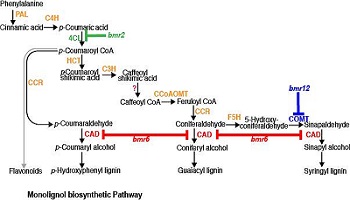

Title: Modifying lignin content and composition to improve sorghum for bioenergy

Time : 14:50-15:10

Biography:

Abstract:

James B Houser

Appalachian State University, USA

Title: Cold climate anaerobic digestion

Time : 15:10:15:30

Biography:

Abstract:

Jacob K Jensen

Michigan State University, USA

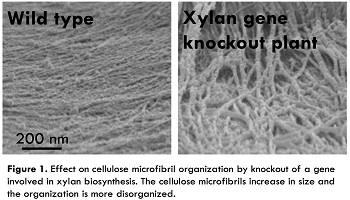

Title: Genetic manipulation of the cell wall hemicellulose component as a route to improved feedstock materials for biofuels production

Time : 15:30-15:50

Biography:

Jacob K Jensen has his expertise in plant cell wall materials and their formation. His particular area of interest is cell wall molecular architecture and design principles.

Abstract:

Sally krigstin

University of Toronto, Canada

Title: Storage activity in the woody biomass supply chain: Mitigating GHG emissions and biomass degradation

Time : 15:50-16:10

Biography:

Abstract:

Networking & Refreshment Break 16:10-16:20 @ Foyer

- Biomass | Bioenergy | Session-2

Location: Dorothy

Chair

Vosatka Miroslav

Institute of Botany Czech Academy of Sciences, Czech Republic

Co-Chair

Niclas Scott Bentsen

University of Copenhagen, Denmark

Session Introduction

Adam Campen

Imreys inc., USA

Title: Demonstrating operational stability and high returns on investment using additives in biomass burning power boilers

Time : 16:20-16:40

Biography:

Abstract:

Christina Dorado

USDA-ARS, USA

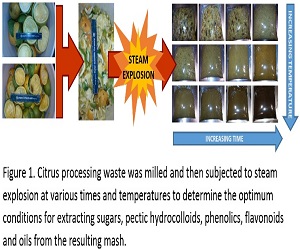

Title: Steam Explosion for the extraction of sugars, pectic hydrocolloids, phenolics, flavonoids and oils from Citrus sinensis

Time : 16:40-17:00

Biography:

Abstract:

Serpil Özmıhçı

Dokuz Eylül University, Turkey

Title: Evaluation of rise husk for bio-hydrogen production

Time : 17:00-17:20

Biography:

Abstract:

Vosatka Miroslav

Institute of Botany Czech Academy of Sciences, Czech Republic

Title: Ecological management of fast growing trees plantations and biorefinery of added value products from biomass

Time : 17:20:17:40

Biography:

Abstract:

Janaina Camile Pasqual

Pontifical Catholic University of Paraná, Brazil

Title: Water-Energy-Food Nexus: Biogas background and perspectives for Brazil and the United States by 2050

Time : 17:40-17:55

Biography:

Abstract:

Naz Orang

University of Toronto, Canada

Title: Predictive statistical model for optimized biomass boiler operation

Time : 17:55-18:10

Biography:

Abstract:

Augstina E.phram

Centre RAPSODEE, France

Title: Hydrogen chloride removal from wood waste-derived syngas using inorganic sorbents

Time : 18:10-18:25

Biography:

Abstract:

Rajesh MUNIRATHINAM

Centre RAPSODEE, France

Title: Calcium phosphates as a novel support material for catalysis in Fischer-Tropsh synthesis

Time : 18:25-18:40

Biography:

Abstract:

Rachna Dhir

University of California Riverside, USA

Title: Comparing pretreatment and subsequent hydrolysis maximum total sugar yielding conditions organosolv pretreatment to CELF pretreated poplar

Time : 18:40-18:55

Biography:

Abstract:

- Entrepreneur investment meet | Special session |

Location: Dorothy

Chair

Malgorzata Slupska

POET, USA

Session Introduction

Malgorzata Slupska

POET, USA

Title: Advances in the commercial ethanol production

Time : 11:10-11:30

Biography:

Abstract:

Jason Bootsma

Flint Hills Resources, USA

Title: Innovation at Flint Hills Resources

Time : 11:30-11:50

Biography:

Abstract:

Brooks Henningsen

Mascoma LLC, USA

Title: Improving first and second generation ethanol production with biotech yeast

Time : 11:50-12:10

Biography:

Abstract:

Herman Pel

DSM, Netherlands

Title: Optimizing enzyme cocktails and process conditions for production of cellulosic ethanol

Time : 12:10-12:30

Biography:

Abstract:

Sarah Teter

Novozymes, USA

Title: Customized enzymes and robust yeast- Novozymes’ solutions for cellulosic biorefineries

Time : 12:30-12:50

Biography:

Abstract:

Lunch Break: Lunch Break 12:50-13:30 @ Foyer

- Special talk

Location: Dorothy

Session Introduction

Jeff Passmore

Passmore Group Inc., Canada

Title: Getting to Scale: Choosing the right financing tool, and the right location

Time : 13:30-13:55

Biography:

Abstract:

- Advnaced biofuels | Biorefineries | Bioethanol

Location: Dorothy

Chair

Wolfgang Bauer

Michigan State University, USA

Co-Chair

Kesen Ma

University of Waterloo, Canada

Session Introduction

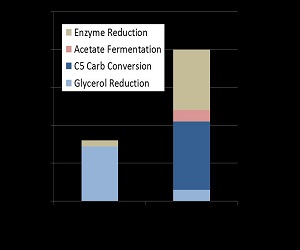

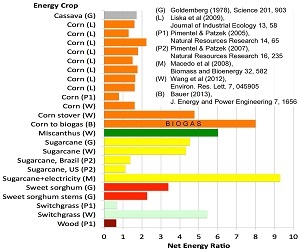

Wolfgang Bauer

Michigan State University, USA

Title: Comparison of bio-ethanol and biogas: Net energy ratio, total yield, and greenhouse gas emissions

Time : 13:55-14:15

Biography:

Abstract:

Daniel thran

Helmholtz Centre for Environmental Research (UFZ), Germany

Title: Biofuels between manifold expectations - How to assess their potential for sustainable transportation?

Time : 14:15-14:35

Biography:

Abstract:

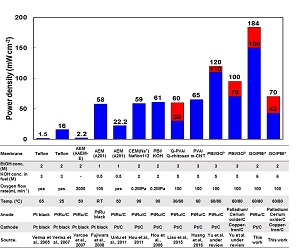

Shingjiang Jessie Lue

Chang Gung University, Taiwan

Title: Direct ethanol fuel cell performance using polyzenzimidazole/graphene oxide nanosheets electrolyte membrane

Time : 14:35-14:55

Biography:

Abstract:

Ian Rowe

U.S. Department of Energy, USA

Title: Engineered carbon cycling strategies for advanced net-zero carbon Biofuels

Biography:

Abstract:

Leandro Soter de Mariz e Miranda

UFRJ, Brazil

Title: Making a bridge between biomass and hydrocarbon in a standard refinery

Time : 14:55-15:15

Biography:

I Graduated in Pharmacy in 2001 and obtained my PhD in 2007 working on the synthesis of natural products. After obtaining my PhD I moved to the Pharmochemical Industry to work on the P&D department in nucleoside chemistry, searching for new synthetic strategies for the synthesis of clinically important nucleosides. In 2011 I Joined the Federal University of Rio de Janeiro and an assistant Professor. In 2011 I went to the University Of Cergy-Pontoise, France, as an Invited Professor to work on Nucleosides against HCV. My research interests are Biocatalysis, Nucleoside and Carbohydrate Chemistry. In 2012 the interest on carbohydrate chemistry led me to work with Lignocellulosic Biomass, in a project with the aim to transform it, in order to allow its introduction into the FCC Unit for the synthesis of green hydrocarbons.

Abstract:

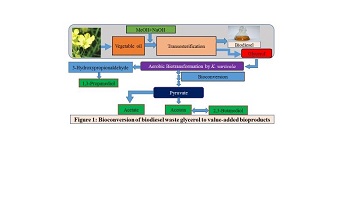

Wensheng qin

Lakehead University, Canada

Title: Effective microbial production of 2,3-butanediol from Biodiesel derived crude glycerol

Time : 15:35-15:55

Biography:

Abstract:

Networking & Refreshment Break 15:55-16:05 @ Foyer

Kesen Ma

University of Waterloo, Canada

Title: Thermostable pyruvate decarboxylases are key enzymes in the alcohol fermentation at high temperatures

Time : 16:05-16:25

Biography:

Abstract:

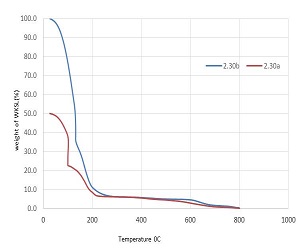

Nuwan Sella Kapu

University of British Columbia, Canada

Title: Bamboo: A fast-growing feedstock for a biorefinery

Time : 16:25-16:45

Biography:

Abstract:

Franklin Kalu

Heriot-Watt University, UK

Title: The potential black liquor has to improve the sustainability of kraft process if used as feedstock for kraft biorefinery

Time : 16:45-17:00

Biography:

Abstract:

Amanpreet Singh

Engineers India Limited, India

Title: India BioFuel industry- Challenges, Opportunities and business strategies

Time : 17:00-17:15

Biography:

Abstract:

Funmilayo Faloye

University of KwaZulu-Natal, South Africa

Title: Microwave-assisted organic acid pretreatment of starch based agro-residue: Assessment of fermentable sugar and bioethanol production

Time : 17:15-17:30

Biography:

Abstract:

M Ali Mandegari

University of Stellenbosch, South Africa

Title: Fossil fuel co-combustion of lignocellulosic sugarcane biorefineries: Techno-economic analysis (TEA) and life cycle assessment (LCA)

Time : 17:30-17:45

Biography:

Abstract:

- Workshop

Location: Dorothy

Session Introduction

Koji Hashimoto

Tohoku Institute of Technology, Japan

Title: Synthesized natural gas production by dually fluidized bed gasification of woody biomass and subsequent methanation

Time : 11:10 - 11:35

Biography:

Koji Hashimoto is the Professor of Emeritus Tohoku Institute of Technology and Visiting Scholar Tohoku Institute of Technology. He has completed his Postdoctoral studies at the Division of Applied Chemistry, ational Research Council,Canada. He has published over 540 papers in scientific journals in addition to review articles and book chapters. He is the Editorial Board member of "Corrosion Science and the Electrochemical Society of Japan, the Society of Chemical Engineers, Japan. In particular, he has built a prototype plant for global CO2 recycling in 1995 on the roof top of the Institute for Materials Research, Tohoku University.

Abstract:

The current atmospheric carbon dioxide concentration on our planet exceeded 400 ppm, which corresponds to the atmosphere in Pliocene 3.5 million years ago. Our planet had to spend 2.5 million years to decrease it to the pre-industrial level of about 280 ppm mostly by solid carbonate formation as a result of weathering dissolution of rocks on elevated Himalayan Tibet mountain massif due to the heavy rain of the monsoon. It is, therefore, impossible for us to decrease carbon dioxide from 400 ppm to 280 ppm. Only the effort we can do is to decrease carbon dioxide emissions. Our effort of the use of woody biomass in the form of synthesized natural gas is one of the solutions. We formed synthesized natural gas by efficient gasification of woody biomass and subsequent methanation. For gasification of whole-wood pellets including bark, we carried out dual fluidization in both combustion furnace and gasification furnace. In this system we performed gasification by thermal decomposition and steam gasification avoiding nitrogen contamination and achieved more than 75% cold gas efficiency of the calorific value of the wood, obtaining high concentration of hydrogen. We used a novel tar reformer with a catalyst and attained 99.9% tar reformation in the pilot scale experiment, without deterioration for 8000 h in the laboratory scale experiment. After gasification, we sent a mixture of hydrogen, carbon monoxide, carbon dioxide and steam to the methanation reactor, which uses Ni-ZrO2 type oxide catalysts. The reactor converts a mixture of 4 volumes of hydrogen and one volume of carbon dioxide to methane with almost 100% methane selectivity and about 90% conversion efficiency at 300 °C and ambient pressure. In fact, carbon monoxide at first reacted with steam shifting to hydrogen and carbon dioxide (CO+H2O=H2+CO2). Thus, the amount of methane formed was a quarter of the sum of hydrogen and carbon monoxide in the reactant gas (4H2+CO2=CH4+2H2O). We performed a demonstration at 38 Nm3/h of reactant gas with 40% steam to form methane with more than 70% calorific efficiency. The process simulation showed that the methane purity is higher than 99% after membrane separation.

- Special talk

Location: Dorothy

Session Introduction

Jim Grey

Chair of renewable industries and CEO IGPC Ethanol Inc., Canada

Title: Special talk

Time : 11:35-12:00

Biography:

Abstract:

- Biodiesel | Biogas | Algae Biofuels

Location: Dorothy

Session Introduction

Antonio Domingos Padula

UFRGS, Brazil

Title: A competitiveness analysis of alternative oilseeds for biodiesel production in Brazil

Time : 12:00 - 12:20

Biography:

Antonio Domingos Padula is Professor at the School of Management of the Federal University of Rio Grande do Sul (UFRGS), holds a degree in Mechanical Engineering from the School of Engineering of São José dos Campos (1980), Diplome D'Etudes Approfondies in Business Administration - Université de Sciences Sociales of Grenoble (1988) and doctorate in Business Administration - University of Social Sciences of Grenoble (1991). It operates in the following areas: production chains, agribusiness, bioenergy, industrial competitiveness, production strategy and operations. Participation in national and international projects: Coordinator CAPES-FIPSE-USA Project; Cooperation UFRGS-Nanjing Agricultural University (China); Cooperation UFRGS-Beijing Technology and Business University; UFRGS-UC-Berkeley Cooperation; Researcher in the Structuring Project of agroenergy in RS (FINEP and FAPERGS) and in the Pathways to Innovation Project in RS (CNPq-Pronex). This researcher participates with ad hoc consultant for CNPq, CAPES, FINEP, ... and in national and international journals.

Abstract:

The quest to develop energy matrices with higher content of renewable energy has encouraged efforts in different countries to produce and use liquid biofuels as substitutes for petrol and diesel. Biodiesel is a fuel produced from renewable sources such as vegetable oils and animal fats. In Brazil, the production and use of biodiesel is regulated by the institutional framework proposed by the national program for the production and use of biodiesel (Programa Nacional Produção e Uso de Biodiesel Produção - PNPB). The diversification of raw materials to produce biodiesel is among the main PNPB objectives. However, in Brazil, this biofuel is predominantly produced using soybeans (83%). In order to understand the reasons for the predominance of this oilseed, this research evaluated the competitiveness, economic efficiency and political effects of biodiesel production using three alternative oilseeds in Rio Grade do Sul state (the largest biodiesel producer in Brazil): Soybean, canola and sunflower. The research was conducted using the Policy Analysis Matrix (PAM) approach, which assists in analyzing and defining public policies and identifying possible market failures that might influence the economic outcomes of agribusiness chains, while assessing the competitiveness and efficiency of those systems. The results indicate that the three oilseed chains are competitive. Nevertheless, the superiority of biodiesel production from soybean chain is notable, as this chain is well organized, more competitive and more economically efficient. On the other hand, policy distortions were observed which disadvantage the private and social profitability of the three studied chains, such as the farmer’s payment system based on the seed weight, although the percentage of oil and prices differ substantially among the different raw materials, besides the significant differences in technological standards adopted in the different crops production. The results indicate the need to review the tax incentive policies, subsidies and payments to farmers of the different crops used for the production of biodiesel.

Ana Paula Alonso

The Ohio State University, USA

Title: A systems approach to improve oil synthesis in alternative crops

Time : 12:20 - 12:40

Biography:

Ana Paula Alonso is Associate Professor in the Dept. of Molecular Genetics, and Director of the Targeted Metabolomics Laboratory at The Ohio State University. A major focus of the Alonso Lab is the regulation of carbon partitioning through central metabolism. In plants, central metabolism carries carbon to the production of valuable storage compounds, such as sugars, proteins, starch, oils, and cellulose. Therefore understanding carbon partitioning is of fundamental relevance to plant fitness, fruit quality, seed yield and germination, and to designing novel approaches for breeding and genetic engineering of crops. For this purpose, the Alonso Lab combines metabolomics and 13C-based metabolic flux analysis - association of modern biochemistry with mathematical modeling. Current research aims at: Enhancing the flow of carbon towards the production of unusual fatty acids for biofuel and industrial applications and understanding the effect of biotic and abiotic stresses on plant metabolism.

Abstract:

Statement of the Problem: Physaria fendleri is a Brassicaceae that produces hydroxy fatty acids (HFAs) in its embryos; a type of oil that is very valuable and widely used in the industry of cosmetics, lubricants, biofuels... The goal of this study is to design an effective strategy for improving HFAs production by Physaria. Indeed, free of toxins and rich in HFAs, Physaria is an attractive alternative to imported castor oil, and is hence in the verge of commercialization. Moreover, Physaria has tremendous potentials for oil production, has a short maturity time and is not used for food compared to other oilseed crops. HFA production could theoretically be enhanced by classical breeding or genetic engineering approaches, however a lack of knowledge of the metabolic pathways underlying oil synthesis in Physaria seeds presents a major constraint. This study aims to find potential biochemical step(s) that limit(s) oil synthesis, which will serve as targets for future crop improvement.

Methodology & Theoretical Orientation: To advance towards this goal, we determined the intracellular metabolite levels (metabolomics) in Physaria embryos at different stages of development. For this purpose, we have developed novel and highly sensitive methodologies using state-of-the-art liquid chromatography tandem mass spectrometry (LC-MS/MS). The contribution of each pathway to fatty acid synthesis in terms of carbon, reductant and energy provision is being assessed by measuring the carbon flow through the metabolic network.

Findings: The metabolomics study highlighted the metabolites and pathways that were active in Physaria embryos and important for oil production. We are now performing a 13oC-Metabolic Flux Analysis (fluxomics) to build a map of carbon flow through central metabolism.

Conclusion & Significance: This study describes the combination of innovative tools that will pave the way for controlling seed composition in promising alternative crops.

Biography:

Anh N Phan has expertise in the field of reactor engineering/process intensification, biofuel processing and biorefining of waste biomass. She is also interested in kinetic modeling and catalysis. She has published more than 25 papers in high-impact factor journals with h-index of 14. Since 2013, her research has also focused on cold plasma technology and its applications in chemical processes, biorefining and waste treatment.

Abstract:

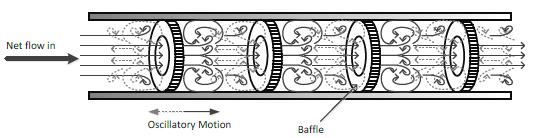

Biodiesel, a mixture of fatty acid esters formed from a transesterification of triglyceride containing feedstock with a short chain alcohol with or without catalyst, is an alternative to petro-diesel. Biodiesel is superior to petro-diesel because it has low sulfur content, high flash point temperature and lubricity and is biodegradable. It is produced from sustainable feedstock (i.e., vegetable oil, microalgae, waste oil), therefore reducing greenhouse gas (CO2) emissions. Biodiesel production is commonly carried out in batch mode in the presence of alkali catalyst and the required reaction time is up to 2 hours in order to obtain biodiesel that meets a fuel standard (i.e., EN14214). Transesterification is a two-phase reaction therefore the rate of the reaction is mass transfer-controlled. Mixing plays an important role throughout the process due to the low miscibility of oil and methanol initially and byproduct glycerol and esters in the final stages. If the mixing is insufficient, stratification (separation) could occur, therefore reducing reaction rates and this phenomenon is particularly pronounced as the phase separation removes the catalyst from the reaction mixture due to the much better solubility of sodium/potassium hydroxide in the glycerol phase. Oscillatory mixing can be effective method of eliminating mass transfer limitations in two-phase liquid systems due to its mode of mixing. An oscillatory baffled reactor (OBR), a form of continuous plug flow reactor was used to intensify the process. Biodiesel can be produced at an industrially acceptable level (>95%) in 2-5 minutes reaction time, approximately a 60-80% reduction in reactor size to obtain the same throughput. The reactor can be used for multi-stage operations and for two-stage biodiesel production for high free fatty acid feedstock. Another advantage of OBR is that, the scale up is predictable, meaning that conditions obtained in laboratory scales can be used for pilot/industrial scales.

Lunch Break 13:00-14:00 @ Foyer

A. Rajendiran

Bharat Petroleum corporation ltd, India

Title: Antiwear study on petroleum base oils with esters

Time : 14:00 - 14:20

Biography:

A Rajendiran is presently working as a Deputy General Manager (R&D) Bharat Petroleum Corporation Ltd in Mumbai, India. Dr.A.Rajendiran has completed his Ph.D from Annamalai University (Public University),Tamil Nadu,India He has 15 years of experience on development of lubricants. He has been involved in developing industrial products, Automotive specialty products and bio degradable lubricants. He was handling various base oils including synthetic base oil like ester base oil, PAO and PAG base oils etc. He has wide experience in NMR, FTIR spectral studies. Prior to this, he worked as the in-charge of Quality control lab about 12 years. He had experience of Motor sprit, High speed diesel, Furnace oil and Kerosene. He has wide experience on testing of testing fuels including Aviation fuels and lubricants, Chennai.He is the life member of The Indian Science Congress Association, India and Tribology society of India. Also he is the member(FRSC) Royal society of chemistry, London

Abstract:

Petroleum based mineral oils have been popularly used for manufacturing lubricants for industrial applications. However, due to concern of environmental pollution, the trend is to attempt to migrate to environment friendly and biodegradable lubricants, by using vegetable oils and synthetic esters, as these too can function as lubricants. This study covers our findings that substantial reduction in friction and wear can be achieved by mixing various proportions of mineral base oils and esters, without adding any conventional antiwear additives. Also, this study reveals the optimum dosage of esters used for reduction of wear and friction. This study is a useful tool for development of lubricants for industrial applications.

Luis F Barahona

CICY, Mexico

Title: Biofuels production from microalgae extracts (green diesel and biokerosene)

Time : 14:20 - 14:40

Biography:

Luis F Barahona has been working on biofuels production from agro-industrial residues. The processes are developed at laboratory scale but focused on the use of regional biomass and easy scale-up. He has applied biotechnological and chemical expertise to better understand the effects of process conditions on biofuels yields as well as sustainable processes.

Abstract:

The production of alternative bio jet fuels is mainly driven by environmental concerns and dependence on fossil fuels. Renewable feed stocks have been studied to provide biofuels with high energy densities, good cold flow properties and stability. Non edible oils and microalgae oils have been used to synthesize bio jet fuel and proved by several airlines. Oil palm, Jatropha, Camelina and microalgae are the most common feed stocks used until now. Due to their productivity, microalgae have good potential to be used as feedstock for biofuels production. Several studies have been carried out to assess their potential to produce three main chemical fractions: Lipids, carbohydrates and proteins that can be converted into biodiesel, bioethanol, biohydrogen and methane. In our group, we are studying the adaptation of the freshwater microalga Scenedesmus obliquus to synthetic wastewater and molasses ascarbon source. The effect of culture time on lipid profiles and the synthesis of biofuels from the microalgal extracts will be discussed.

Giovanni Antonio Lutzu

Oklahoma State University, USA

Title: Feasibility of using brewery wastewater for biodiesel production and nutrient removal by scenedesmus dimorphus

Time : 14:40 - 15:00

Biography:

Giovanni Antonio Lutzu is an Environmental Biologist, has strong interest on the use of microalgae for environmental remediation and as a priceless source of biofuels and high-value added products. He has obtained his PhD at University of Cagliari, Italy, investigating the growth kinetics of microalgae in batch and semibatch photo-bioreactors. Later, during his Postdoctoral Fellowship at the QIBEBT, China, he has focused his attention to the extraction of lipids relevant to the production of microalgal biofuels and to the enhancement of biomass as feedstock for high-value natural products. His ultimate goal as a Scientist has been to explore the feasibility of using wastewaters as a culture medium to enhance lipid and bioproducts accumulation in microalgae. Presently, he is carrying out research at BAE-OSU on the feasibility of using isolated Oklahoma native microalgae strains for the treatment of wastewater generated during the fracking activity for the extraction of oil and gas.

Abstract:

A new type of wastewater, which has potentially been recognized as an appreciable source of nutrients for microalgae cultivation, is represented by the brewery wastewater produced by the brewing industry. This work investigates the potential use of this effluent as a medium for the cultivation of the oleaginous species Scenedesmus dimorphus with the double aim of removing nutrients and to produce biomass as feedstock for biodiesel. For this purpose, effects of nitrogen (61.8-247 mg L−1), phosphorous (1.4-5.5 mg L−1) and iron (1.5-6 mg L−1) concentrations on growth, nutrients uptake, lipid accumulation and fatty acids profile of this microalga were investigated. Results showed that brewery wastewater can be used as a culture medium even if nitrogen and phosphorous concentrations should have been modified to improve both biomass (6.82 g L−1) and lipid accumulation (44.26%). The analysis revealed a C16-C18 composition of 93.47% fatty acids methyl esters with a relative high portion of unsaturated ones (67.24%). High removal efficiency (>99%) for total nitrogen and total phosphorous and a reduction of up to 65% in chemical oxygen demand was achieved, respectively. The final microalgae biomass, considering its high lipid content as well as its compliance with the standards for the quality of biodiesel and considering also the high removal efficiencies obtained for macronutrients and organic carbon makes the brewery wastewater a viable option as a priceless medium for the cultivation of microalgae.

Ashwin Gajra

Reliance Industries Limited, India

Title: Recycle of process streams for sustainable production of algae biofuels

Time : 15:00 - 15:20

Biography:

Ashwin Gajra has more than 15 years of experience in developing products and processes for Biotech applications. He has developed, scaled up and transferred technology for biofuels, biopharmaceuticals, diagnostic markers and waste water treatment and animal feed. He is currently developing cost-effective processes for separation and dewatering of algae, for biofuels and other high value applications.

Abstract:

In spite of several benefits offered by microalgae biomass as a feedstock for biofuels, high material and energy costs linked with production process poses a challenge of sustainability. Along with large volumes of water, nutrients (Nitrogen and Phosphorus) are among the substantial costs in cultivating algae. One of the many strategies to reduce the cost of cultivating algae is to lower the water footprint and reduce the nutrient requirement by efficient recycle of process streams. At Reliance Industrial Limited (RIL), the process development effort has an extensive focus on recycle of various process streams, to develop sustainable algae to oil process. This presentation will summarize the work carried out through targeted research leading to optimum recycle of harvested water and nutrients from different process streams; without any adverse impact on growth and productivity. Small-scale development work was carried out outdoors (in aquarium), in a semi-turbidostat mode, with water and nutrients supplementation from recycled process streams. Impact of inhibitors/toxic matter due to build-up in the system was studied. The results indicate a significant improvement in cost savings due to recycle of water and nutrients.

Javid Hussain

Institute of Chemical Sciences University of Peshawar, Pakistan

Title: Microbial based biofuel production: potential impact on the control of global warming

Time : 15:20 - 15:40

Biography:

Javid Hussain graduated (PhD) in 2016 from the UFBA and MSU, United States and where his supervisors were Drs. Iracema Nascimento and Dr. Wei Liao. In 2010, He received a Master’s degree in Environmental Chemistry from the Institute of Chemical Sciences, University of Peshawar, Pakistan and in 2011 was admitted to MPhil program at the same institute. During his MPhil year, He received PhD offers from three countries (Australia, Brazil and South Korea). He accepted The World Academy of Sciences Award for PhD study.He has been published more than 12 papers in international peer-reviewed journals. He received grants from The World Academy of Sciences (TWAS) to attend bioenergy conferences and events held in South America, North America, and Europe, and he delivered lectures at international events in four continents.

Abstract:

Environmental pollution and global warming is one of the biggest issues of world today. Environmental pollution is mainly due to anthropogenic way, mostly caused by human daily activities, usage of fossil fuels. In turn these are causing an increase in global warming. Although there are advantages of the fossil fuels in industry, but on the other hand the same fuels are also contributing the biggest amount of pollutants to the environment e.g., particulate matters, greenhouse gases which are involved in acid rain. For the last decade the world big economy pillars i.e., US, China, Brazil, Australia and some other European Countries have been giving great attention to solve the issue by increasing the production of biodiesel which are derived from various organic resources such as oleaginous fungi, microalgae, plants and animal fat. Biodiesel production is presently based on edible vegetable oils. The commercialization is challenged by high production cost and has been of the great concern regarding food vs. fuel competition. The proposed study is focused on finding non-edible oil sources such as algae. These microorganisms minimize competition with conventional agriculture, have fast growth rates, utilize a wide variety of water source, recycle stationary emissions of carbon dioxide and have high areal productivity. If we do commercialize it in market then the only option left is to produce microbial-based biodiesel, which have very good fuel properties and reduce the CO2 concentration in atmosphere. Moreover, this talk will outline recent progress made in understanding and optimizing the use of microorganisms such as algal, fungus which act as producers and decomposers in ecosystem. If scientifically and adequately explored, it will play an important role in energy sector, environmental sustainability and natural socio-ecological systems.

Henry T Bedoya

University of Life Sciences, Norway

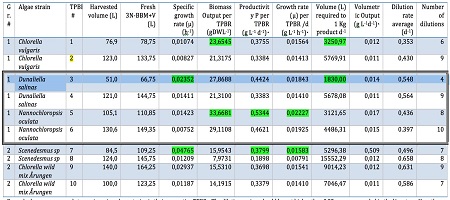

Title: Production of Microalgae Biomass (MAB): A cost-efficient, profitable, sustainable and quality upscaling of five commercial microalgae strains in greenhouse at northern latitudes

Time : 15:40 - 16:00

Biography:

Henry T. Bedoya Has background in biological, botanical and microbiological studies and degrees from Kharkov´s National State University, Ukraine; University of Oslo, Norway and The University of Life Sciences of Norway. Field studies in food production at greenhouse conditions and specialization in microalgae biomass (MAB) production in greenhouse at northern latitudes. This journey started in Ukraine and continued in Norway with production and delivery of the MAB for the EU project under the Research for SME program titled, “Operation SWAT” under contract n: 286840 and comprehended cost-effective MAB production in two processes: upscaling and harvesting by flocculation and filtration. SWAT involved R&D institutions from Czech Republic, Germany, Poland, Spain UK and Norway. Bedoya´s work at NMBU and IGV-GmbH results and findings, generated the core data for the recreation of a conveyor belt filter device from the wastewater treatment industry (Salsnes Filter Series), into a device specialized in MAB harvesting.

Abstract:

Andisheh Yazdanpanaha

University of Western Ontario, Canada

Title: Effect of trace metals addition on food waste anaerobic digestion

Time : 16:00 - 16:20

Biography:

Andisheh Yazdanpanah is a a graduate student at Western University, London, Ontario

Abstract:

This study presents the impact of trace elements supplementation (TEs: Fe [50-400 mg/L], Ni [0.5-20 mg/L], Co [0.1-5 mg/L], Se [0.005-0.8 mg/L] and Mo [2-20mg/L]) individually as well as in mixtures on the specific methanogenic activity (SMA), maximum specific methane production rate (SMPRmax) and apparent hydrolysis rate constant (Kh) of food waste (FW) anaerobic digestion. Seriesof batch anaerobic digestion tests with kitchen FW as substrate were performed at various concentrations of different TEs under mesophilic conditions using Fe-rich inoculum (≈1.7 g/L). The results of this study revealed that addition of TEs adversely impacted methanogenic activity especially at the maximum concentrations of Fe, Ni, Co and Se by 47%, 70%, 33% and 37%, respectively. The effect of Mo on the methane production and SMA rate was neutral. Fe, Ni, and Co significantly affected the methane productions at elevated concentrations unlike Se and Mo. Impacts of individual supplementation of Fe, Co, Ni, Se and Mo on the SMPRmax and Kh were negligible except for Fe (400 mg/L) which moderately reduced the SMPRmax by 24%. Similar results to the control (no TEs addition), were also observed for the Kh when different mixtures of TEs were used, however, unlike the Kh, positive impacts on the SMPRmax (12%-22% enhancement) were obtained, possibly indicating the synergy. It is postulated that the high concentration of Fe in the used inoculum played an indispensable role in reducing the bioavailable fraction of metals in the form of free metal via precipitation, co-precipitation and adsorption in both single and multiple TEs addition forms.