Day 1 :

Keynote Forum

Lee Rybeck Lynd

Dartmouth College, USA

Keynote: Cellulosic biofuels: Realizing climate benefits and new processing paradigms

Time : 09:00-09:30

Biography:

Abstract:

Keynote Forum

Marc Rosen

University of Ontario Institute of Technology, Canada

Keynote: Bioenergy and energy sustainability

Time : 09:30-10:00

Biography:

Abstract:

Keynote Forum

Rajai H Atalla

Cellulose Sciences International, Inc., USA

Keynote: Nanoporous celluloses, previously unknown forms, as the best primary feedstocks for energy, chemical and agricultural feed production

Time : 10:00-10:30

Biography:

Abstract:

Keynote Forum

Henrik V Scheller

Lawrence Berkeley National Laboratory, USA

Keynote: Engineering of plants for improved conversion into biofuels and bioproducts

Time : 10:45-11:15

Biography:

Abstract:

Networking & Refreshment Break 10:30-10:45 @ Foyer

Keynote Forum

Donald L Smith

McGill University, Canada

Keynote: Enhanced production of feedstock biomass: Biostimulants as a low-cost, low-carbon approach

Biography:

Abstract:

- Special session

Location: Dorothy

Chair

Donald L Rockwood

University of Florida, USA

Session Introduction

Donald L Rockwood

University of Florida, USA

Title: Eucalyptus trees for bioenergy

Time : 11:45-12:05

Biography:

Abstract:

Ronald S Zalesny Jr

United States Department of Forest Service, USA

Title: Fast growing poplars for bioenergy

Time : 12:05:12:25

Biography:

Abstract:

Timothy A Volk

State University of New York College of Environmental Science and Forestry, USA

Title: Shrub willow for bioenergy and ecosystem services

Time : 12:25-12:45

Biography:

Abstract:

Lunch Break 12:45-13:30 @ Foyer A

- Biomass | Bioenergy

Location: Dorothy

Chair

Prabir Basu

Dalhousie University, Canada

Co-Chair

Charles M. Cai

Universitty of California Riverside, USA

Session Introduction

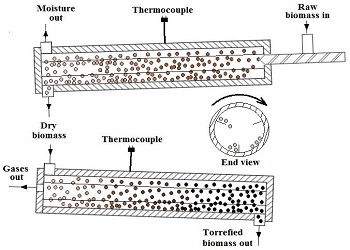

Prabir Basu

Dalhousie University, Canada

Title: A comprehensive study on production of torrefied biofuel using inclined rotary reactor

Time : 13:30-13:50

Biography:

Abstract:

Charles M. Cai

University of California Riverside, USA

Title: Biomass deconstruction towards total carbon utilization for future biorefineries

Time : 13:50-14:10

Biography:

Abstract:

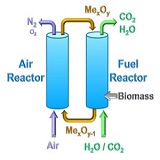

Alberto Abad

ICB-CSIC, Spain

Title: Biomass combustion with CO2 capture by chemical looping

Time : 14:10-14:30

Biography:

Abstract:

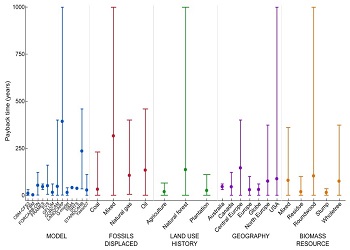

Niclas Scott Bentsen

University of Copenhagen, Denmark

Title: Carbon debt of forest bioenergy - Fact or fantasy?

Time : 14:30-14:50

Biography:

Abstract:

Scott Sattler

USDA-ARS, USA

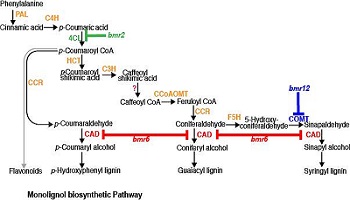

Title: Modifying lignin content and composition to improve sorghum for bioenergy

Time : 14:50-15:10

Biography:

Abstract:

James B Houser

Appalachian State University, USA

Title: Cold climate anaerobic digestion

Time : 15:10:15:30

Biography:

Abstract:

Jacob K Jensen

Michigan State University, USA

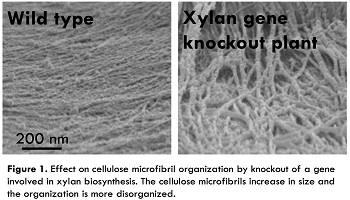

Title: Genetic manipulation of the cell wall hemicellulose component as a route to improved feedstock materials for biofuels production

Time : 15:30-15:50

Biography:

Jacob K Jensen has his expertise in plant cell wall materials and their formation. His particular area of interest is cell wall molecular architecture and design principles.

Abstract:

Sally krigstin

University of Toronto, Canada

Title: Storage activity in the woody biomass supply chain: Mitigating GHG emissions and biomass degradation

Time : 15:50-16:10

Biography:

Abstract:

Networking & Refreshment Break 16:10-16:20 @ Foyer

- Biomass | Bioenergy | Session-2

Location: Dorothy

Chair

Vosatka Miroslav

Institute of Botany Czech Academy of Sciences, Czech Republic

Co-Chair

Niclas Scott Bentsen

University of Copenhagen, Denmark

Session Introduction

Adam Campen

Imreys inc., USA

Title: Demonstrating operational stability and high returns on investment using additives in biomass burning power boilers

Time : 16:20-16:40

Biography:

Abstract:

Christina Dorado

USDA-ARS, USA

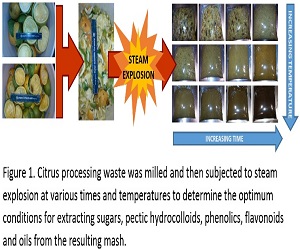

Title: Steam Explosion for the extraction of sugars, pectic hydrocolloids, phenolics, flavonoids and oils from Citrus sinensis

Time : 16:40-17:00

Biography:

Abstract:

Serpil Özmıhçı

Dokuz Eylül University, Turkey

Title: Evaluation of rise husk for bio-hydrogen production

Time : 17:00-17:20

Biography:

Abstract:

Vosatka Miroslav

Institute of Botany Czech Academy of Sciences, Czech Republic

Title: Ecological management of fast growing trees plantations and biorefinery of added value products from biomass

Time : 17:20:17:40

Biography:

Abstract:

Janaina Camile Pasqual

Pontifical Catholic University of Paraná, Brazil

Title: Water-Energy-Food Nexus: Biogas background and perspectives for Brazil and the United States by 2050

Time : 17:40-17:55

Biography:

Abstract:

Naz Orang

University of Toronto, Canada

Title: Predictive statistical model for optimized biomass boiler operation

Time : 17:55-18:10

Biography:

Abstract:

Augstina E.phram

Centre RAPSODEE, France

Title: Hydrogen chloride removal from wood waste-derived syngas using inorganic sorbents

Time : 18:10-18:25

Biography:

Abstract:

Rajesh MUNIRATHINAM

Centre RAPSODEE, France

Title: Calcium phosphates as a novel support material for catalysis in Fischer-Tropsh synthesis

Time : 18:25-18:40

Biography:

Abstract:

Rachna Dhir

University of California Riverside, USA

Title: Comparing pretreatment and subsequent hydrolysis maximum total sugar yielding conditions organosolv pretreatment to CELF pretreated poplar

Time : 18:40-18:55