Francisco GarcÃa Labiano

ICB-CSIC, Spain

Title: Bioenergy production through chemical looping processes

Biography

Biography: Francisco GarcÃa Labiano

Abstract

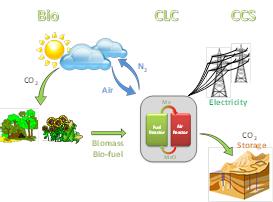

This work presents an overview of the recent advances in bio-CLC technology within the key strategies arising nowadays to mitigate climate change. The Paris Agreement, the new treaty of the United Nations Framework Convention on Climate Change (UNFCCC), urges to decarbonize the world energy systems in the near future in order to limit the increase in the average world temperature to 2ºC above pre-industrial levels. To reach this goal, CO2 emissions should start to decrease by 2020 and become negative by the end of the century. Among the different options, most of the low-carbon scenarios rely on the use of BECCS (Bioenergy and Carbon Capture and Storage) as mandatory technologies to reach negative emissions. In this sense, Chemical Looping Combustion (CLC) is considered one of the most promising CCS technologies for power plants and industries because its inherent CO2 capture avoids the energetic penalty present in other competing technologies. CLC process is based on the use of a solid oxygen carrier to transfer the oxygen from air to the fuel avoiding direct contact between them. The technology has undergone a great development during last 15 years including operational experience in continuous units and oxygen carrier’s manufacture. In addition, the new Chemical Looping with Oxygen Uncoupling (CLOU) process represents a qualitative step forward in solid fuel combustion due to the use of materials with capability to release oxygen. There are several renewable energy sources that can be used in chemical looping processes, including both solid and liquid fuels. The use of biomass in CLC represents important advantages compared to conventional biomass combustion. Besides CO2 negative balance, higher thermal efficiency, NOx formation reduction and lower corrosion in heat exchangers have been reported. In addition, several renewable liquid fuels, such as bioethanol can be also used both in combustion (CLC) and reforming (CLR) processes for heat/electricity and syngas/H2 production, respectively. In summary, the use of renewable fuels in chemical looping processes represents at this moment a very promising opportunity for future green energy development.