Day 2 :

Keynote Forum

Ajit Sapre

Reliance Industries, India

Keynote: Biofuels and bio-chemicals: One perspective

Time : 09:00-09:30

Biography:

Abstract:

Keynote Forum

Majid Hosseini

The University of Texas Rio Grande Valley, USA

Keynote: Technical challenges of large-scale microalgae harvesting for feed, food, and biofuels production

Time : 09:30-10:00

Biography:

Dr. Hosseini has earned both his PhD and MS degrees in Chemical Engineering from the University of Akron, in Ohio, USA. He has also completed an MSE degree in Manufacturing Engineering at UTRGV in Texas, USA, and a Bachelor’s degree in Chemical Engineering at Sharif University of Technology in Tehran, Iran. Dr. Hosseini has edited book and book chapters, co-invented patents application technologies, and authored multiple peer reviewed research articles. He has served as a key speaker at national and international conferences and meetings and has been actively engaged in technology development. He is a persistent reviewer of leading international journals.

Abstract:

Presently, commercially produced microalgae are used in supplemental nutritional products for humans and animals. There is a great potential for microalgae to be used in food/feed supplements, biofuels production, electricity generation, carbon dioxide biofixation, etc. Throughout the world, many variations on cultivation methods, species of microalgae, harvesting means and the biomass processing technology have been implemented. Even though microalgae biomass has been rigorously studied in both the laboratory and in the field for years, its usefulness is impeded by the difficulty experienced in its large scale cultivation thereby making it commercially infeasible. Nevertheless, there are multiple issues that must be addressed before the widespread adoption of algal biomass production technology. Several species are already being used commercially in raceway ponds, but are still not produced in high enough quantities or in a cost effective manner that is required for fuels and feeds. While algae biomass demand continues to increase globally, producers require technological developments that drive cost reduction while retaining and elevating the quality of the product. Low cost, efficient and scalable harvesting and subsequent dewatering methods require technological advancement in order to drive cost reduction of downstream processing and ultimately biofuel production. The favorability of the carbon and energy balance is what determines the microalgae feedstock’s viability for the production of biofuel. In order to achieve large-scale production levels, not only must processing costs be drastically cut, but more importantly is the development of algae strains that are highly productive and can be cheaply harvested. The systems used for the identification, promotion and utilization of algal biomass are sought after by producers and processors alike so as to ensure profitability, supply security, eco-consciousness, sustainability, market competitiveness, and etc. This work detailed the challenges that microalgae biomass production and utilization face which span the breadth of the algal production chain. Constraints, both chemical and physical in nature, that obstruct mass production and application of large scale algal biomass is also addressed herein. Comparisons between various microalgae harvesting methods and their potential for scalability are discussed. Furthermore, a discussion on the technical, economic and environmental barriers that must be surmounted prior to the introduction of microalgae-based products into the global market is presented.

Keynote Forum

Ange Nzihou

Centre RAPSODEE, France

Keynote: Innovative catalysts for the conversion of greenhouse gases (CO2 and CH4) from biowastes to energy and chemical

Time : 10:00-10:30

Biography:

Abstract:

Networking & Refreshment Break 10:30-10:40 @ Foyer

Keynote Forum

Wei-Hsin Chen

National Cheng Kung University, Taiwan

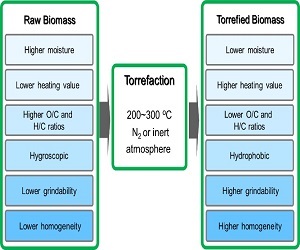

Keynote: Recent progress in torrefaction for upgrading solid biomass fuels

Time : 10:40-11:10

Biography:

Abstract:

- Entrepreneur investment meet | Special session |

Location: Dorothy

Chair

Malgorzata Slupska

POET, USA

Session Introduction

Malgorzata Slupska

POET, USA

Title: Advances in the commercial ethanol production

Time : 11:10-11:30

Biography:

Abstract:

Jason Bootsma

Flint Hills Resources, USA

Title: Innovation at Flint Hills Resources

Time : 11:30-11:50

Biography:

Abstract:

Brooks Henningsen

Mascoma LLC, USA

Title: Improving first and second generation ethanol production with biotech yeast

Time : 11:50-12:10

Biography:

Abstract:

Herman Pel

DSM, Netherlands

Title: Optimizing enzyme cocktails and process conditions for production of cellulosic ethanol

Time : 12:10-12:30

Biography:

Abstract:

Sarah Teter

Novozymes, USA

Title: Customized enzymes and robust yeast- Novozymes’ solutions for cellulosic biorefineries

Time : 12:30-12:50

Biography:

Abstract:

Lunch Break: Lunch Break 12:50-13:30 @ Foyer

- Advnaced biofuels | Biorefineries | Bioethanol

Location: Dorothy

Chair

Wolfgang Bauer

Michigan State University, USA

Co-Chair

Kesen Ma

University of Waterloo, Canada

Session Introduction

Wolfgang Bauer

Michigan State University, USA

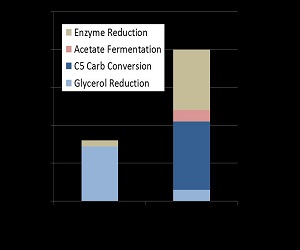

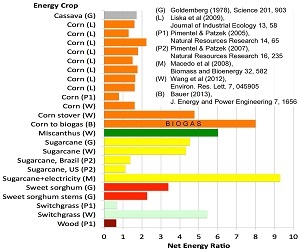

Title: Comparison of bio-ethanol and biogas: Net energy ratio, total yield, and greenhouse gas emissions

Time : 13:55-14:15

Biography:

Abstract:

Daniel thran

Helmholtz Centre for Environmental Research (UFZ), Germany

Title: Biofuels between manifold expectations - How to assess their potential for sustainable transportation?

Time : 14:15-14:35

Biography:

Abstract:

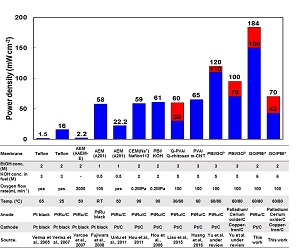

Shingjiang Jessie Lue

Chang Gung University, Taiwan

Title: Direct ethanol fuel cell performance using polyzenzimidazole/graphene oxide nanosheets electrolyte membrane

Time : 14:35-14:55

Biography:

Abstract:

Ian Rowe

U.S. Department of Energy, USA

Title: Engineered carbon cycling strategies for advanced net-zero carbon Biofuels

Biography:

Abstract:

Leandro Soter de Mariz e Miranda

UFRJ, Brazil

Title: Making a bridge between biomass and hydrocarbon in a standard refinery

Time : 14:55-15:15

Biography:

I Graduated in Pharmacy in 2001 and obtained my PhD in 2007 working on the synthesis of natural products. After obtaining my PhD I moved to the Pharmochemical Industry to work on the P&D department in nucleoside chemistry, searching for new synthetic strategies for the synthesis of clinically important nucleosides. In 2011 I Joined the Federal University of Rio de Janeiro and an assistant Professor. In 2011 I went to the University Of Cergy-Pontoise, France, as an Invited Professor to work on Nucleosides against HCV. My research interests are Biocatalysis, Nucleoside and Carbohydrate Chemistry. In 2012 the interest on carbohydrate chemistry led me to work with Lignocellulosic Biomass, in a project with the aim to transform it, in order to allow its introduction into the FCC Unit for the synthesis of green hydrocarbons.

Abstract:

Wensheng qin

Lakehead University, Canada

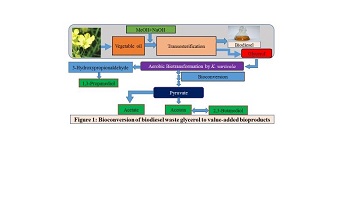

Title: Effective microbial production of 2,3-butanediol from Biodiesel derived crude glycerol

Time : 15:35-15:55

Biography:

Abstract:

Networking & Refreshment Break 15:55-16:05 @ Foyer

Kesen Ma

University of Waterloo, Canada

Title: Thermostable pyruvate decarboxylases are key enzymes in the alcohol fermentation at high temperatures

Time : 16:05-16:25

Biography:

Abstract:

Nuwan Sella Kapu

University of British Columbia, Canada

Title: Bamboo: A fast-growing feedstock for a biorefinery

Time : 16:25-16:45

Biography:

Abstract:

Franklin Kalu

Heriot-Watt University, UK

Title: The potential black liquor has to improve the sustainability of kraft process if used as feedstock for kraft biorefinery

Time : 16:45-17:00

Biography:

Abstract:

Amanpreet Singh

Engineers India Limited, India

Title: India BioFuel industry- Challenges, Opportunities and business strategies

Time : 17:00-17:15

Biography:

Abstract:

Funmilayo Faloye

University of KwaZulu-Natal, South Africa

Title: Microwave-assisted organic acid pretreatment of starch based agro-residue: Assessment of fermentable sugar and bioethanol production

Time : 17:15-17:30

Biography:

Abstract:

M Ali Mandegari

University of Stellenbosch, South Africa

Title: Fossil fuel co-combustion of lignocellulosic sugarcane biorefineries: Techno-economic analysis (TEA) and life cycle assessment (LCA)

Time : 17:30-17:45