Prabir Basu

Dalhousie University, Canada

Title: A comprehensive study on production of torrefied biofuel using inclined rotary reactor

Biography

Biography: Prabir Basu

Abstract

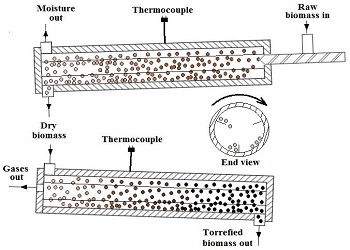

Torrefaction produces a char product with higher specific energy, lower equilibrium moisture content than untreated material, brittleness requiring low grinding energy and resistive to environmental degradation. Additionally, torrefaction provides a product of uniform qualities. Torrefaction process, thus, appears as excellent solution for pretreating biomass. A two-stage, inclined continuous rotary torrefier with novel flights has been developed in the Biomass Conversion Laboratory at Dalhousie University for improving biomass torrefaction process as is shown in Figure-1. Experimental work on torrefaction of fine Poplar wood particles (0.5-1.0 mm) in the torrefier was undertaken for a deeper understanding of the working of such torrefiers where the volatile gas released was used as the torrefaction medium instead of nitrogen. The rotary torrefier is operated under different operating conditions by varying its rotational speed, tilt angle and temperature. Chemical and physical properties of the torrefied products included ultimate and proximate analysis, polymeric analysis, energy density, mass yield, energy yield and bulk density were measured. Temperature and conversion at different interior points along the length of the rotary reactor while the biomass was being progressively torrefied in it were measured. Fixed carbon content, volatile and energy density of biomass undergoing torrefaction varied linearly along the length of the torrefier. Typical values of change in heating value, mass yield and energy yield of torrefied biomass was 40%, 34% and 48%, respectively for 300 °C and 5 RPM and 1° of tilt angle. Results showed that temperature is the most important parameter in the torrefaction process.