Gopal P Agarwal

Indian Institute of Technology Delhi, India

Title: Partial separation of simulated lignocellulosic hydrolyzate via nanofiltration

Biography

Biography: Gopal P Agarwal

Abstract

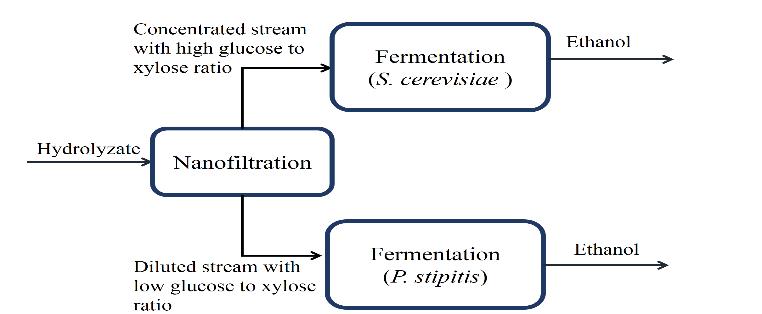

In recent years, bioconversion of lignocellulosic biomass into ethanol has been identified as a promising technology for producing liquid biofuels. However, lignocellulosic biomass hydrolysis produces a mixture of hexose and pentose sugars, which together are difficult to ferment to produce ethanol. Moreover, it also contains several fermentation inhibitors such as acetic acid, furfural, 5-hydroxyl methyl furfural and some phenolic compounds. Thus in literature several recombinant strains, capable of simultaneous uptake of glucose and xylose have been developed [1]. Along with use of recombinant strains, nanofiltration has also been applied to concentrate the sugars in hydrolyzate [2, 3], and for simultaneously removal of inhibitors from hydrolyzate [2-4], which increased the overall sugar consumption and improved the ethanol yield. However, genetically modified strains may suffer from low yields, low productivities and genetic instability. In this study, a new strategy is used where nanofiltration is applied for separating the xylose from a synthetic hydrolyzate mixture (as shown in Fig. 1). Sjoman et al [5] had already shown that glucose and xylose can be partially separated by using nanofiltration membranes, however, their aim was towards complete separation. On the other hand in the proposed process, hydrolyzate is divided into two streams one has higher glucose to xylose ratio (retentate stream) and another has lower glucose to xylose ratio (permeate stream). Most of the inhibitors, present in hydrolyzate get enriched along with glucose in the retentate stream, which can be easily fermented by S. cerevisiae. Permeate stream with lower inhibitors concentration and lower glucose to xylose ratio can be effectively fermented by suitably adapted P. stipitis [6]. In this study simulated hydrolyzate solutions were experimentally examined using commercially available spiral wound nanofiltration modules. Experiments were performed in the volume reduction (dynamic) mode at variety of operating conditions by using different cut-off nanofiltration membranes in order to optimize the operating conditions and to identify the best suitable cut-off for maximizing the separation. The optimization study involved would be to minimize presence of xylose in the glucose enriched stream by combination of suitable concentration factor and separation factor.

Fig. : Proposed strategy for processing of hydrolyzate from lignocellulosic biomass via nanofiltration

Recent Publications:

1. B. Hahn-Hagerdal, M. Galbe, M.F. Gorwa-Grauslund, G. Lide´n and G. Zacchi (2006). Bio-ethanol – the fuel of tomorrow from the residues of today, Trends in Biotechnology 24, 549-556

2. Sasaki K., Tsuge Y., Sasaki D., Teramura H., Inokuma K. (2015), Mechanical milling and membrane separation for increased ethanol production during simultaneous saccharification and co-fermentation of rice straw by xylose-fermenting Saccharomyces cerevisiae, Bioresource Technology 185:263-268.

3. Sasaki K., Tsuge Y., Sasaki D., Hasunuma T., Sakamoto T., Sakihama Y., Ogino C., Kondo A. (2014) Optimized membrane process to increase hemicellulosic ethanol production from pretreated rice straw by recombinant xylose-fermenting Saccharomyces cerevisiae, Bioresource Technology 169:380-386.

4. Maiti S.K., Thuyavan Y.L., Singh S., Oberoi H.S., Agarwal G.P. (2012) Modeling of the separation of inhibitory components from pretreated rice straw hydrolyzate by nanofiltration membranes, Bioresource Technology 114: 419-427.

5. Sjoman E., Manttari M., Nystrom M., Koivikko H., Heikkil H. (2007) Separation of xylose from glucose by nanofiltration from concentrated monosaccharide solutions, Journal of Membrane Science 292:106-115.

6. Rastogi A., Agarwal G.P. (2016) Nanofiltration mediated process for ethanol fermentation of biomass hydrolyzates by wild-type yeasts presented International Conference on Twenty First Century Energy Needs (ICTFEN)-Materials, Systems and Applications sponsored by IEEE on November 18, 2016.