Ramachandran Sivaramakrishnan

Chulalongkorn University, Thailand

Title: Biorefinery approach of microalgae feedstock for the production of bioethanol and biodiesel

Biography

Biography: Ramachandran Sivaramakrishnan

Abstract

Problem

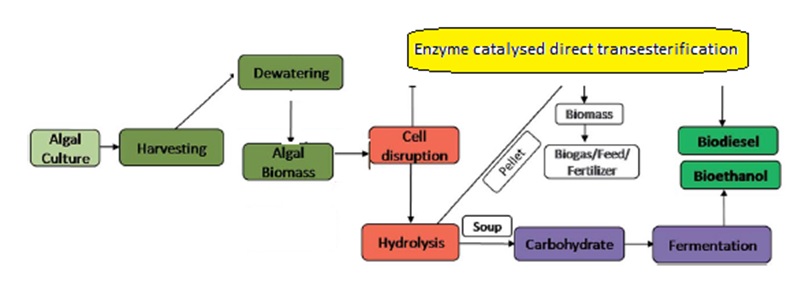

The continued use of fossil fuels depletes the reserves, more than 75% of petroleum based fuels are burnt in the transportation sector. The utilization of global energy is expected to be increased in the future due to increase population and demand. Therefore, there is a need for alternative fuel, which is not only satisfying the need, but also solve the environmental problems. Microalgae feedstocks, a reliable biofuel source, has drawn much attention as an alternative and renewable. This is due to the microalgal species have the excellent photosynthetic efficiencies and the biomass reproducibility potential than any other terrestrial crops. In this study the integrated approach of ethanol and biodiesel production from algal biomass. This integrated method is to develop the microalgae based biorefinery model.

Abstract

The present study focuses on the biorefinery approach of integrated production of bioethanol and biodiesel from microalgae feedstock. Various pretreatment methods were used to determine the maximum recovery of sugars from Scenedesmus sp. The total sugar yield of 84 % was obtained when pretreated separately by acid hydrolysis. The hydrolysate produce 90 % of ethanol (theoretical yield) after the fermentation. Enzyme catalyzed ultrasound assisted direct transesterification of biomass was performed and the maximum of 91% methyl ester yield, 2.6 % glycerol carbonate and 5.6% glycerol dicarbonate was obtained. The integrated process of initial acid hydrolysis produces 84 % of total sugar. The sugar extracted biomass was initiated with enzyme catalyzed direct transesterification with ultrasound irradiation. The obtained hydrolysate was further fermented with S. cerevisiae and at the optimized conditions of fermentation 90 % of ethanol (theoretical yield) was obtained. The conditions of direct transesterification using enzyme were optimized and produces 89 % of biodiesel yield with 2.1 % glycerol carbonate and 4.9 % glycerol dicarbonate. Thus, the microalgal biomass efficiently produces both ethanol and biodiesel as well glycerol carbonate, which could be the biorefinery model for sustainable future development.

Recent Publications:

1. Sivaramakrishnan R. and Aran I. “Direct transesterification of Botryococcus sp. catalysed by immobilized lipase: Ultrasound treatment can reduce reaction time with high yield of methyl ester” , Fuel, Vol.191, pp.363-370 (Publisher – Elsivier)

2. Sivaramakrishnan R. and Aran I. “Purification and characterization of solvent tolerant lipase from Bacillus sp. for methyl ester production from algal oil”, Journal of Bioscience and Bioengineering, Vol. 121, pp.517-522, 2016 (Publisher – Elsevier)

3. Sivaramakrishnan, R. and Muthukumar, K. “Direct transesterification of Oedogonium sp. oil be using immobilized isolated novel Bacillus sp. lipase”, Journal of Bioscience and Bioengineering, Vol.117, pp.86-91, 2013 (Publisher – Elsevier)

4. Sivaramakrishnan, R. and Muthukumar, K. “Production of methyl ester from Oedogonium sp. oil using immobilized isolated novel Bacillus sp. lipase”, Energy & Fuels, Vol. 26, pp.6387−6392, 2012 (Publisher – American Chemical Soceity (ACS))

5. Sivaramakrishnan, R. and Muthukumar, K. “Isolation of thermo-stable and solvent-tolerant Bacillus sp. lipase for the production of biodiesel”, Applied Biochemistry and Biotechnology, Vol.166, pp.1095–1111, 2012 (Publisher - Springer).